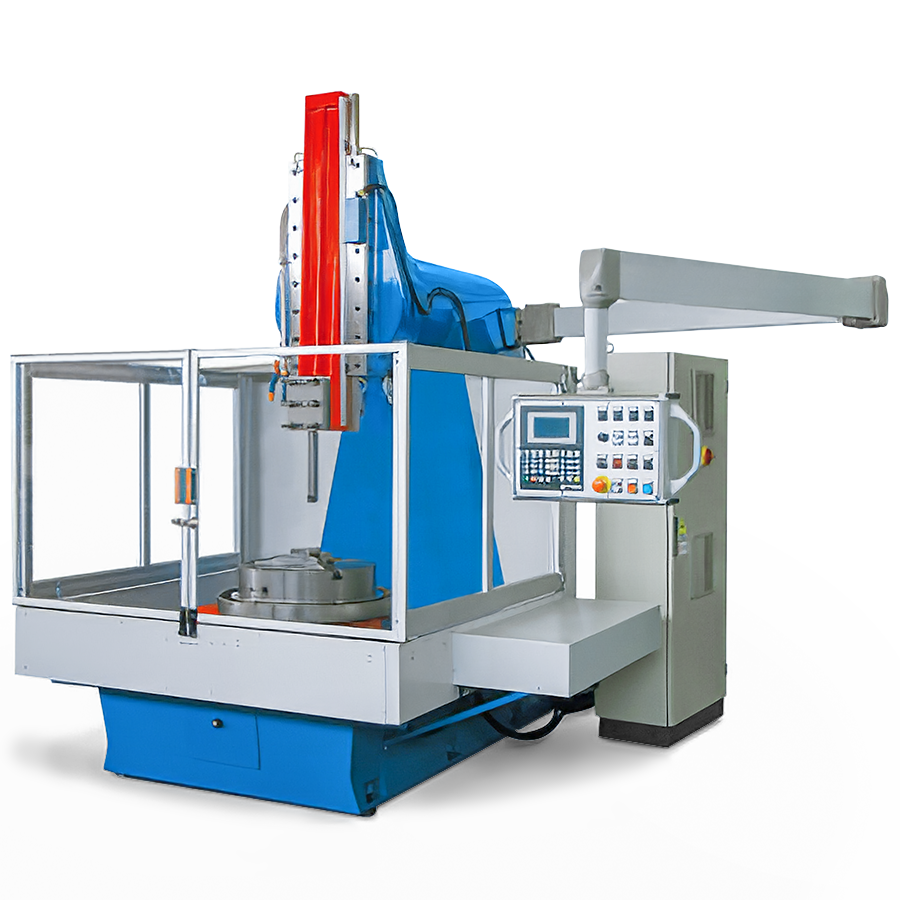

Our Slotting Machine 4AC is the result of 30 years experience and research in design and development of industrial slotting machinery and equipment.

The CAMS slotting machine offers a number of important features :

robust construction: the main structure is manufactured in robust thickness sheet metal (heat treated and processed);

tables in high quality grade cast-iron (grade G30);

the turntable with a working diameter of 1000mm and central 350mm diameter central through hole;

travel surfaces in cast-iron and PTFE with lubrication system designed to substantially reduce the stick/slip effect axes move on recirculating ball screw assemblies;

CAMS has recently improved the head by incorporating in-house designed and developed technological innovations. The ram has been modified in size to offer greater robustness and is driven by a brushless motor transforming it into a machining axis. Gears in an enclosed oil bath connect the drive system to the motor.

Travel surfaces on the head are in cast-in and PTFE ground and scraped.

Machine electrics have been modified offering greater machining performance and flexibility as well as incorporating improved technology:

automatic longitudinal and horizontal pre-programmed and reversible slot machining and automatic rotation of turntable for any required slot depth and diameter.

tool lift obtained by alternating table movements;

once the pre-programmed slot depth has been reached, in automatic the machine performs a number of pre-programmed finishing strokes and the ram stops in position Z- and the workpiece table in automatic returns to machining start cycle position.

The NC machine control offers a simple to use operator / machine interface. Machine data and parameters are displayed on a 10.4 “ touch screen display which is used for entering production and machining programmes. Programming is user friendly and easy to use.

Programmes with zero workpiece can be saved and stored and called up when required. Ram travel is adjusted using the keypad saving on downtimes and tooling times.

Electronic turntable with central through hole to floor with possibility of programming 1500 symmetrical and 999 asymmetrical divisions.

Possibility of machining specific trapezoidal, circular and linear slots.

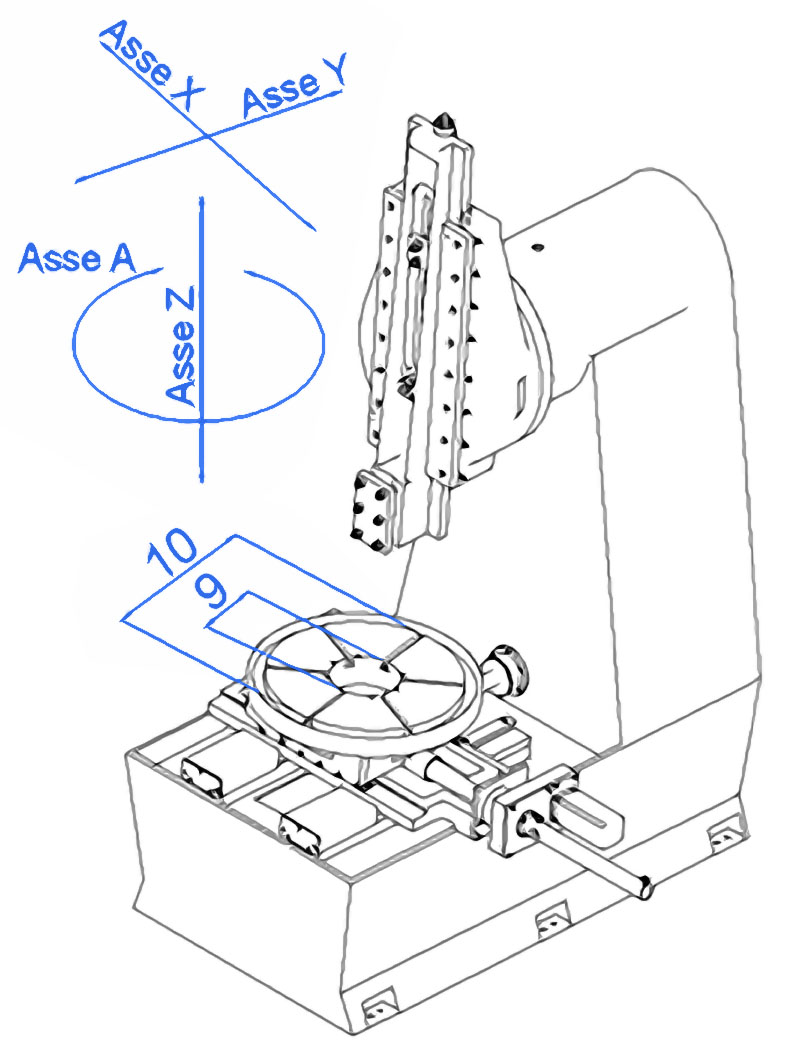

Thanks to the possibility of having a fourth NC axis (axis Z), the operator can machine tapered slots without having to incline the head. This is achieved by interpolating axis Y with axis Z in automatic and programming the machining angle. This model can run in automatic two or more programmes in sequence.

The head tilts on a worm screw assembly 20° in both directions. Machining speed is programmed and varies form zero to a max of 32 m/min and thanks to the potentiometer incorporated into the control panel speed change is stepless.

The NC machining Z axis and corresponding servo-drive offer improved uniform machining compared to conventional slotting machines resulting in a reduction in consumption and wear in the cutting tool.

The software offers the following standard applications:

• slot repeat: this function is for repeating slot machining without having to proceed with machine setup.

• incremental tool lift: with this function enabled the tool is completely raised out of the slot when the ram returns and returns to zero workpiece position.

• slot bottom finishing: in the event the slot is widened the operator has the possibility of milling the bottom of the slot to finish.

• slot side finishing: this function is for widening the slot by milling and finishing the sides.

If required, it is possible to add and incorporate specific software functions and applications:

• decreasing tool feed: this function allows the operator to automatically modify tool feed (machining) using two specific values initial and final tool feed. This function is enabled by entering the two tool feed values.

• chamfering: once having machined the slot it is possible with this function to chamfer slot edges to 45° in automatic.

• tangential slots: this function allows the operator to machine in automatic two or more UNI 7515-76 tangential slots of any width.

The machine is supplied with an electro-pump for the cooling system with a 130 l/min capacity and a metal housing containing the automatic pumps which can be programmed for managing the lubrication system used for greasing the ram, tables and head gears.

Protections on axis Y and oil scraper on axes X and Y

Maintenance tools and machine instruction manual are supplied

Safety protections

Machine designed and manufactured to EC standards and directives.

| TECHNICAL SPECIFICATIONS | 4AC | ||

| Adjustable tool travel from 0 to ( NC controlled axis Z ) | mm | 1500 | |

| 1 | Distance Column/Tool holder | mm | 1000 |

| 2 | Distance Table surface/Head | mm | 1200 |

| 3 | Distance Table surface/earth | mm | 1020 |

| 4 | Distance between tool-holder basis and table centre backwards | mm | 735 |

| 5 | Distance between tool-holder basis and table centre forwards | mm | 365 |

| 9 | Boring in Worktable centre | Ø mm | 350 |

| 10 | Measurements turntable (NC controlled axis A) | Ø mm | 1000 |

| 11 | Max.distance between head surface and ram surface (HPD) | mm | 650 |

| 12 | Max.distance between head surface and ram surface (LHP) | mm | 850 |

| |

Longitudinal Table travel (CN on axis Y) | mm | 1100 |

| Horizontal travel (CN on axis X) | mm | 640 | |

| Max. loading capacity | kg | 3000 | |

| N. of variable stepless strokes | N. strokes/min | 20 | |

| Ram drive motor (brushless) | Kw N × m |

13 50 |

|

| Overall machine dimensions | mm | L =3100 P =3800 H =4900 |

|

| Weight | Kg | 15000 |